| Nominal diameter - water | DN 25 ... DN 50

|

| Nominal pressure - water | PN 40; 63; 100

|

| Nominal diameter - steam | DN 80 ... DN 150

|

| Nominal pressure - steam | PN 25; 40; 63; 100

|

| Nozzles | with full and empty atomization cone, spraying angle 60…90°

|

| Materials | – body, bonnet: 10CrMo 4-5; (1.7335) – head, internal elements: X17CrNi 16-2; (1.4057) – nozzles: X6CrNiMoTi 17-12-2; (1.4571). Use of other materials is possible, but must be agreed upon. |

| Flow coefficient | Kv 0,15...10

|

| Leakage class | V class acc. to PN-IEC 60534-4 |

| Rangeability | 40:1

|

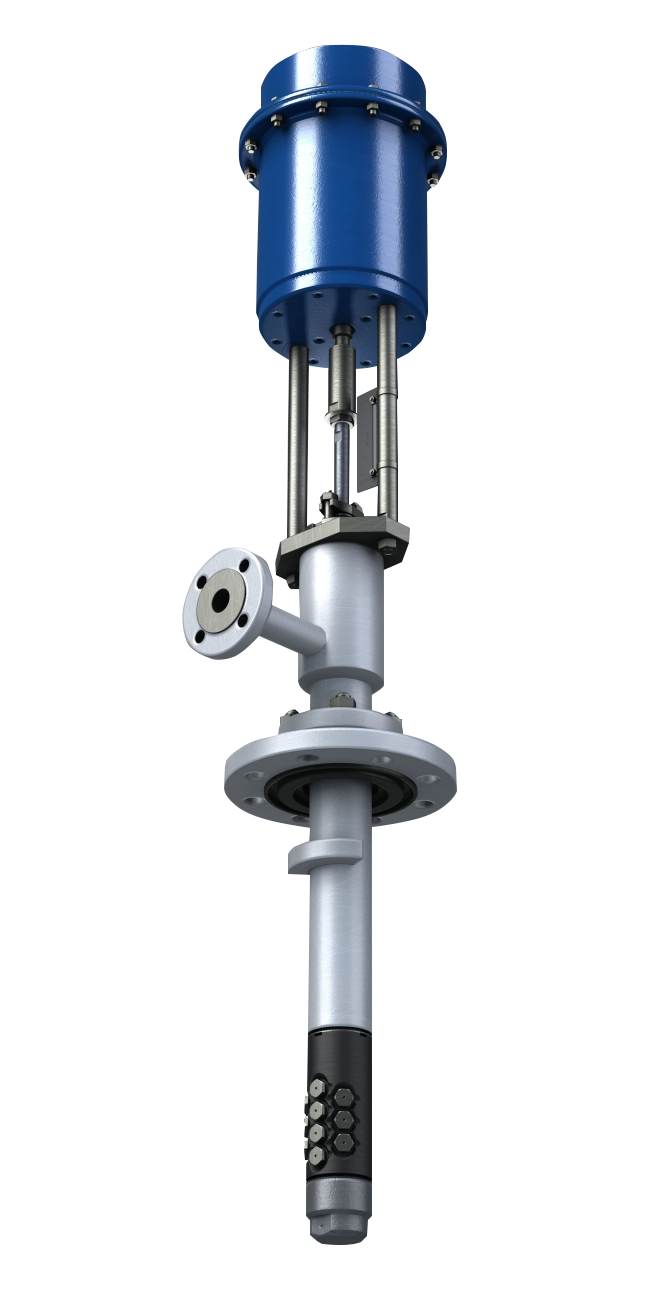

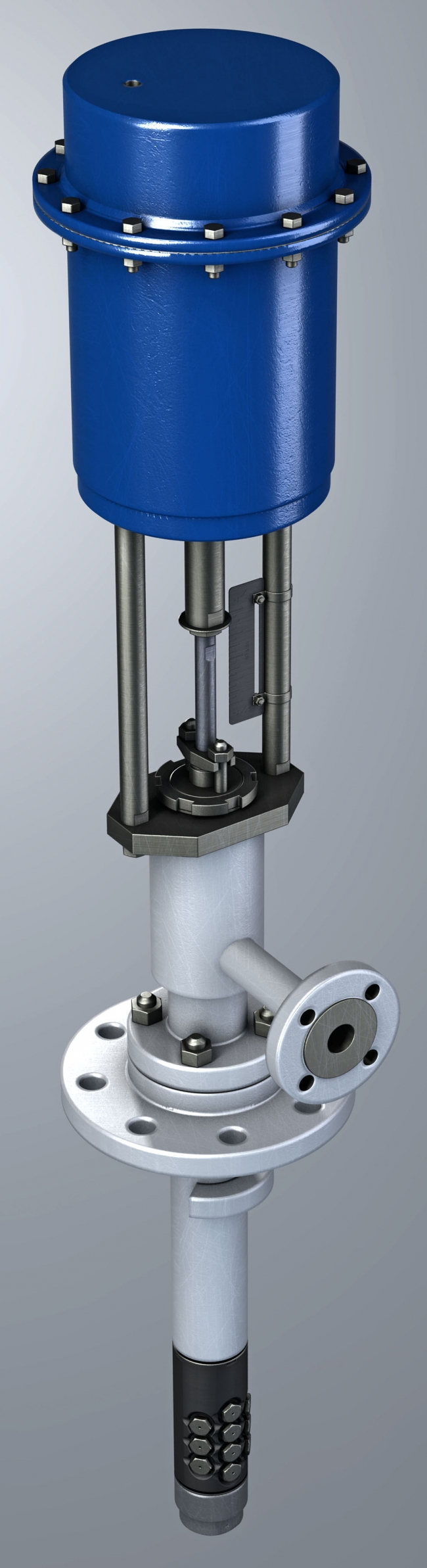

- possible customizing of the device design to adjust flow rates to customers’ demands,

- removing of device vibrations thanks to the support on a pipeline connecting pipe,

- resistance to leakage due to the use of a spiral, elastic metal-graphite gasket at the connecting pipe,

- wide range of flange connections,

- selection of materials according to customers’ demands,

- easy replacement of the seat and other internal components of the desuperheater,

- no welded joints between nozzles and device heads,

- possible application of one type of pneumatic actuators with stroke range up to 100 mm,

- possible use of other actuators according to the customers’ requirements, including pneumatic, electric or hydraulic driving units

After the seat is opened, the cooling water is delivered via the lateral flange connection into the desuperheater’s interior. The head incorporates a series of independent nozzles that are able to atomize water within the full cone of injection with the angle of 90°. Inside the head, there is a piston sealed with steel spring rings. Piston movements enable water flow to subsequent nozzles, which makes the flow characteristic linear, with nearly equal percentage rates. The number and flow capacity of individual nozzles are adjusted accordingly to achieve the desired flow coefficient. Both the head and the nozzles are secured against loosening by a plastic deformation of the securing ring. The desuperheater has split design that allows for easy replacement of seat and internal parts.

We can adjust the desuperheater to your individual needs. In such cases, please contact our technical support specialist.